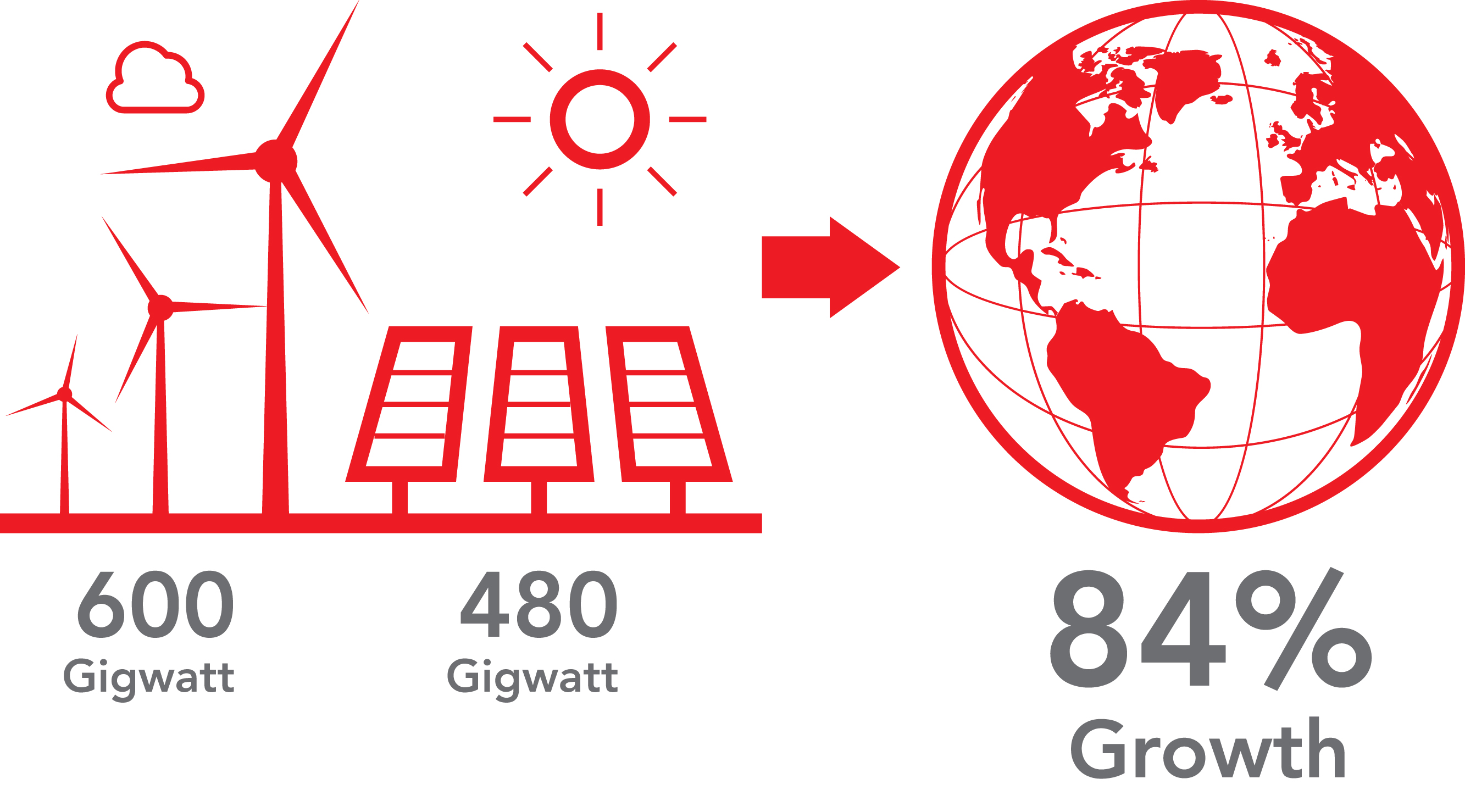

Globally, wind power has now passed a 600 Gigwatt milestone and solar power is not far behind, with capacity already exceeding 480 Gigawatts. These two technologies are proving the most dynamic additions to global renewable energy capacity accounting for 84% of the growth in renewable generation in 2018. This has helped us reach a point where one third of the world’s electricity now comes from natural sources and, with many more projects in the pipeline, we are making steady progress towards meeting the goals of the Paris Climate Change Agreement.

This achievement is due, in no small part, to some extraordinary feats of engineering. The latest wind turbine being built by GE, just outside Rotterdam, is called the Haliade X and will stand 850 feet tall – just 200 feet shorter than the Eiffel tower. While it is being trialed on land, it’s a prototype for a new generation of offshore turbines, each of which will generate 12 megawatts which is enough to power a town of 36,000 people. A single blade is 107metres (350ft) long and necessitated manufacturers, GE to build a new factory in France as the blades were simply too big to ship from their US facility.

Danish company, LM Windpower, recently attracted huge online attention when they transported a blade a mere 88.4m (290ft) long across the country. A feat which took 11 months of planning and hundreds of people to ensure the vast blade arrived at its destination unscathed. Despite their huge size, these masterpieces of modern engineering are manufactured with millimeter precision and manufacturers have experienced real problems with the strains they are subjected to in order undertake what are often long journeys to remote destinations. And this is why it is so vital that producers work with a cargo protection specialist who can engineer solutions that can withstand every potential risk across the journey.

Renewable technologies are routinely shipped around the world and, while wind turbine components pose challenges of scale and weight, solar technologies are incredibly fragile. Many of them travel vast distances being shipped in containers from manufacturing hotspots to areas where demand for solar energy is highest. Damage will render them useless and it is critical that they are secured in a way that has been engineered to ensure they will not move.

We pride ourselves on engineering exceptional solutions to protect any cargo and we have worked with many of the world’s largest engineering contractors to create tailor-made solutions for loads of every conceivable shape and size. Similarly, we have engineered the world’s most secure means of protecting containerized shipments from the forces they will be subjected to over long sea and rail journeys.

In a resource efficient world, it is imperative those precious resources are not wasted due to avoidable damage. Our cargo protection experts will help you avoid damages in transit. To talk to us about how we can protect and sustain your project and drive sustainability across your supply chain, get in touch with your local team today!

For expert advice on cargo securing solutions contact us now

Contact nowCordstrap have specialists in over 50 global locations

Providing physical insurance to the world’s major industries

Delivering cargo protection solutions