Over-tensioning

Excessive tightening of steel strapping and wire can cause them to snap or damage the cargo they are securing.

Under-tensioning

Insufficient tension may lead to strapping or wire loosening, resulting in cargo shifting or falling during transit.

Corrosion and rust

Steel strapping, wire and chains can corrode and rust when exposed to moisture, weakening their strength and structure, reducing their efficacy, and damaging the goods they are meant to protect.

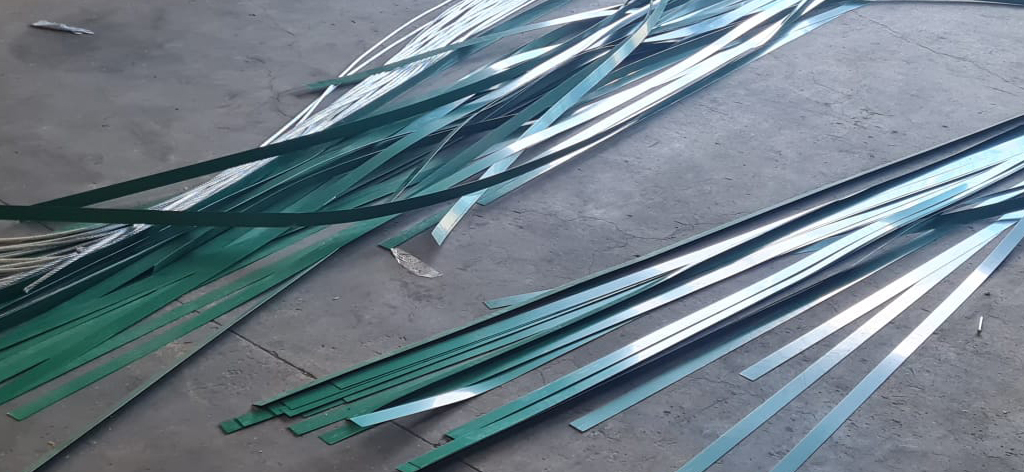

Sharp Edges

Cut steel strapping or wires and chain links often have sharp edges that can cause injuries during cargo handling or unloading.

Rebound Risk

Strapping, wire and chains that snap under tension can whip back violently, posing a significant injury risk to nearby workers.

Vibration and Shock

Vibrations from road or sea travel may cause steel strapping, wire or chains to loosen or fail over time.